Societas Coetus Technologiae Hangzhou Nuzhuo, Ltd.

NUZHUO Officina Productionis Oxygenii Officina Productionis Oxygenii Liquidi Officina Productionis Nitrogenii Officina Separationis Aeris Oxygenii Cryogenici

| Nomen Producti | Instrumenta separationis aeris cryogenici |

| Numerus exemplaris | NZDON-50/80/1XX/150/180/200/AD PERSONALIZATUM |

| Nota | NuZhuo |

| Accessoria | Compressor aeris et systema refrigerationis et expansor& Arca Frigida |

| Usus | Machina productionis oxygenii, nitrogenii et argonis altae puritatis |

| Modellum | NZDON-50/50 | NZDON-80/CLX | NZDON-CLXXX/trecenti | NZDON-260/500 | NZDON-350/700 | NZDON-550/mille | NZDON-750/1500 | NZDON-1200/Anno MM |

| O2 emissus (Nm3/h) | 50 | 80 | CLXXX | 260 | 350 | 550 | DCCCL | 1200 |

| Puritas O2 (%O2) | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 | ≥99.6 |

| N2 0 productum (Nm3/h) | 50 | CLX | trecenti | quingenti | DCC | mille | 1500 | MM |

| Puritas N2 (PPm O2) | 9.5 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| Argonis Liquidi Emissio (Nm³/h) | —— | —— | —— | —— | —— | —— | —— | 30 |

| Puritas Argonis Liquidi (Ppm O₂ + PPm N₂) | —— | —— | —— | —— | —— | —— | —— | ≤1.5ppmO₂ + 4ppmN₂ |

| Puritas Argonis Liquidi (Ppm O₂ + PPm N₂) | —— | —— | —— | —— | —— | —— | —— | 0.2 |

| Consumptio (kWh/Nm³ O₂) | ≤1.3 | ≤0.85 | ≤0.68 | ≤0.68 | ≤0.65 | ≤0.65 | ≤0.63 | ≤0.55 |

| Area Occupata (m³) | 145 | CL | CLX | CLXXX | 250 | 420 | 450 | DCCC |

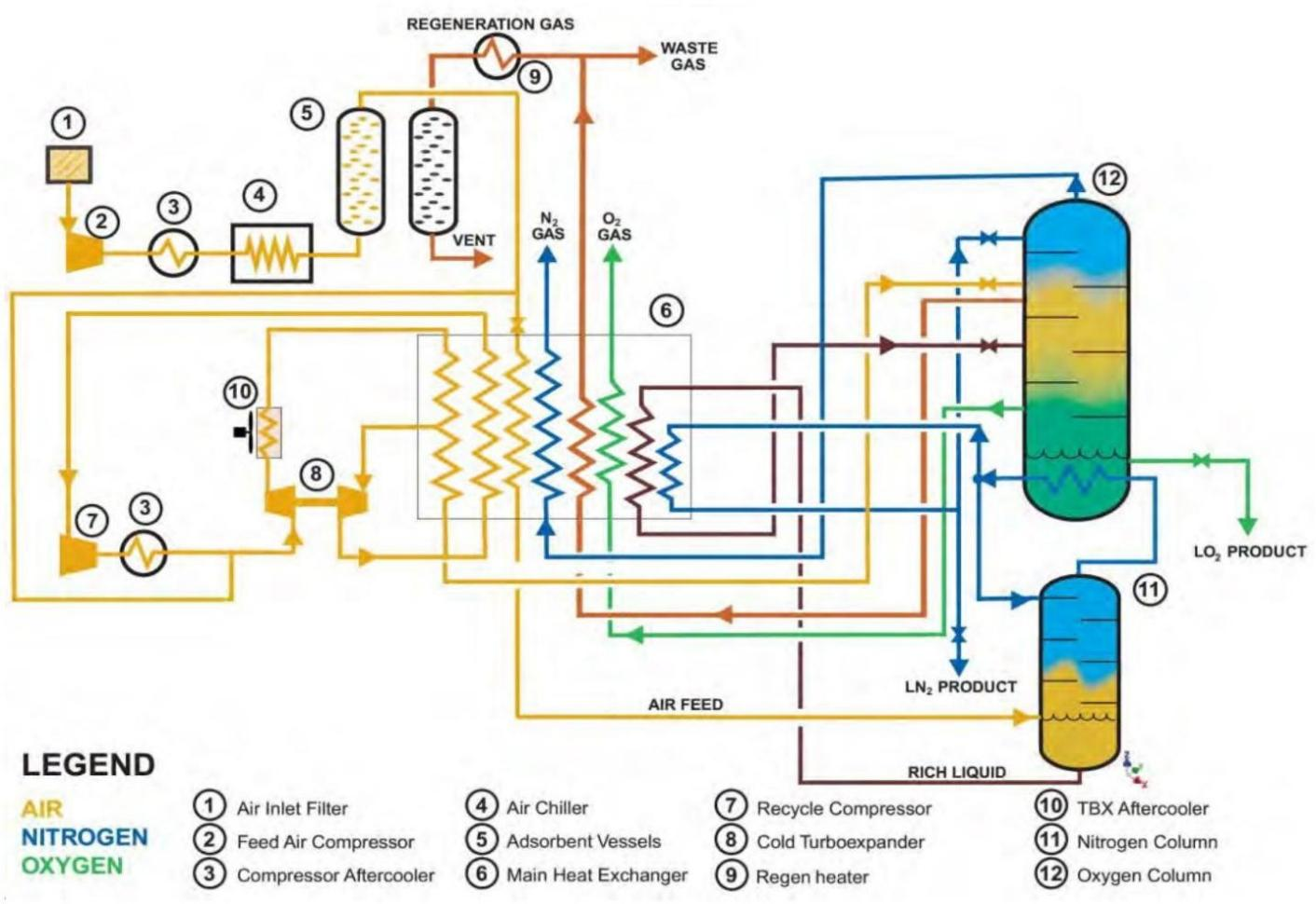

Principium fundamentale separationis aeris est ut rectificatio cryogenica adhibeatur ad aerem in liquidum condensandum et secundum temperaturam evaporationis cuiusque componentis separandum. Turris rectificationis duorum graduum simul nitrogenium purum et oxygenium purum in summo et imo turris superioris obtinet. Etiam fieri potest ut oxygenium liquidum et nitrogenium liquidum ex latere evaporationis et latere condensationis refrigerationis principalis respective extrahantur. Separatio aeris in turri rectificationis in duos gradus dividitur: aer primum in turri inferiore separatur ad nitrogenium liquidum obtinendum et simul aerem liquidum oxygenio locupletatum obtinendum. Aer liquidus oxygenio locupletatus ad turrim superiorem ad rectificationem mittitur ad oxygenium purum et nitrogenium purum obtinendum. Turris superior in duas partes dividitur: cum introitu aeris liquidi ut limite, pars superior est sectio rectificationis, quae gas ascendentem rectificat, componentem oxygenii recuperat, et puritatem nitrogenii purificat, et pars inferior est sectio expurgationis ad componentes nitrogenii in liquido removendos, separandos ad puritatem oxygenii liquidi emendandam.

1. Compressor Aeris: Aer ad 0.5-0.7Mpa a compressore aeris comprimitur.

2. Praerefrigeratio: Aer in unitate praerefrigerationis ad 5-10℃ praerefrigerat, et humiditas separatur.

3. Systema purificationis aeris: Remotio umoris residui, dioxidi carbonis et hydrocarbonum aeris compressi in purificatore cribri molecularis;

4. Expansio aeris: Aer in turbo expansore expanditur et refrigeratur, capacitatem refrigerandi ab instrumento requisitam praebens.

5. Permutatio Caloris: Aer calorem cum oxygenio, nitrogenio, et nitrogenio sordido refluente in permutatore caloris turris fractionationis commutat, et prope temperaturam liquefactionis refrigeratur, et oxygenium, nitrogenium, et nitrogenium sordidum refluens iterum atque iterum ad temperaturam ambientis permutantur;

6. Refrigeratio: Refrigeratio aeris liquidi et nitrogenii liquidi ante suffocationem nitrogenii in refrigeratore.

7. Distillatio: Aer in turri rectificationis rectificatur et separatur, nitrogenium productum in summo turris superioris, oxygenium autem productum in imo turris superioris obtinetur.

SI PLURA COGNOSCERE CUPITIS, NOS CONTACTA: 0086-18069835230

Descriptio Societatis

Certificatum et NUZHUO

Q1: Esne societas mercatoria an fabricator?

Q3: Quamdiu est tempus traditionis tuae?

A: Depending on what type of machine you are purchased. Cryogenic ASU, the delivery time is at least 3 months. Cryogenic liquid plant, the delivery time is at least 5 months. Welcome to have a contact with our salesman: 0086-18069835230, Lyan.ji@hznuzhuo.com

Q4: Quae est politica vestra de qualitate producti curanda?

Q5: Offertisne officium OEM/ODM?

Welcome to have a contact with our salesman: 0086-13516820594, Lowry.Ye@hznuzhuo.comQ6: Utrum productum tuum usurpatum an novum sit? Productum RTS an productum ad usum aptatum?

Categoriae Productorum

In providendis solutionibus mong pu per quinquennium operam damus.

Telephonum: 0086-15531448603

Telephonum: 0086-15531448603 E-mail:elena@hznuzhuo.com

E-mail:elena@hznuzhuo.com